Fully Automatic DBS System

Maximize Efficiency and Accuracy

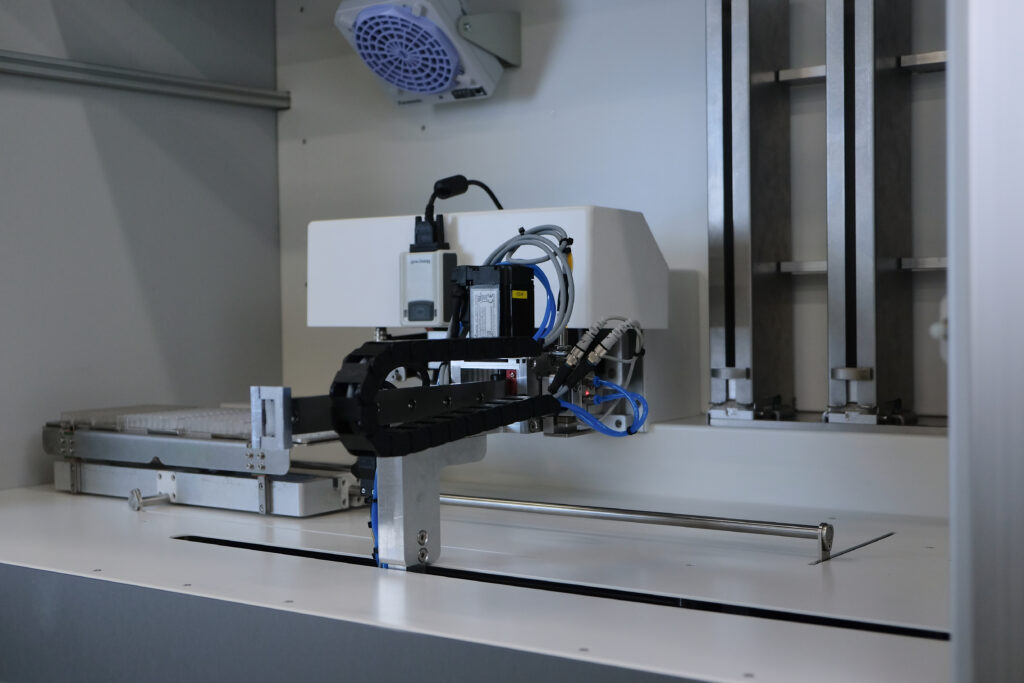

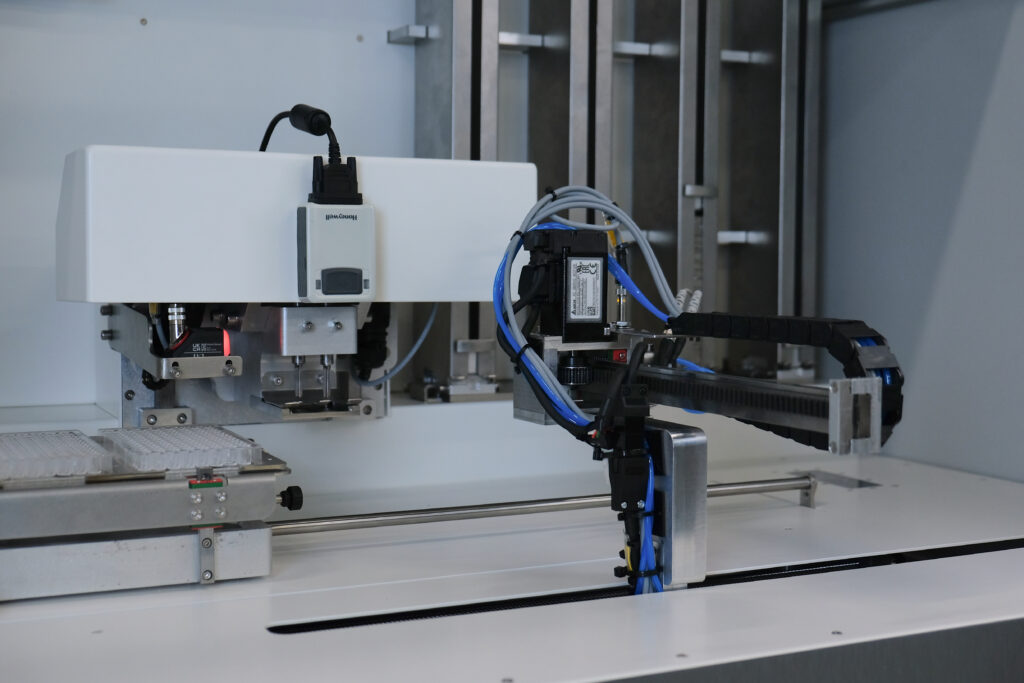

Our fully automatic DBS system is built for high-volume laboratories. With the capability to load multiple DBS cards into the system, the device automates the entire process – from assessing the quality of blood spots, determining the optimal punching location, to executing the punch. With this system, human error is minimized, and consistency in sample preparation is guaranteed.

Benefits:

- Reduces human intervention and error.

- Increases lab productivity and efficiency.

- Delivers consistent and high-quality results.

Key features

- 4 well plates for processing

- Possibility of working with different height wellplates

- High speed 120 card per hour

- Advanced software

- Two removable feeders, each for 100 cards

- Two collectors with the same construction

- Built-in air compressor

- Automatic card scanner

- Samples quality check station

- Punched discs verification

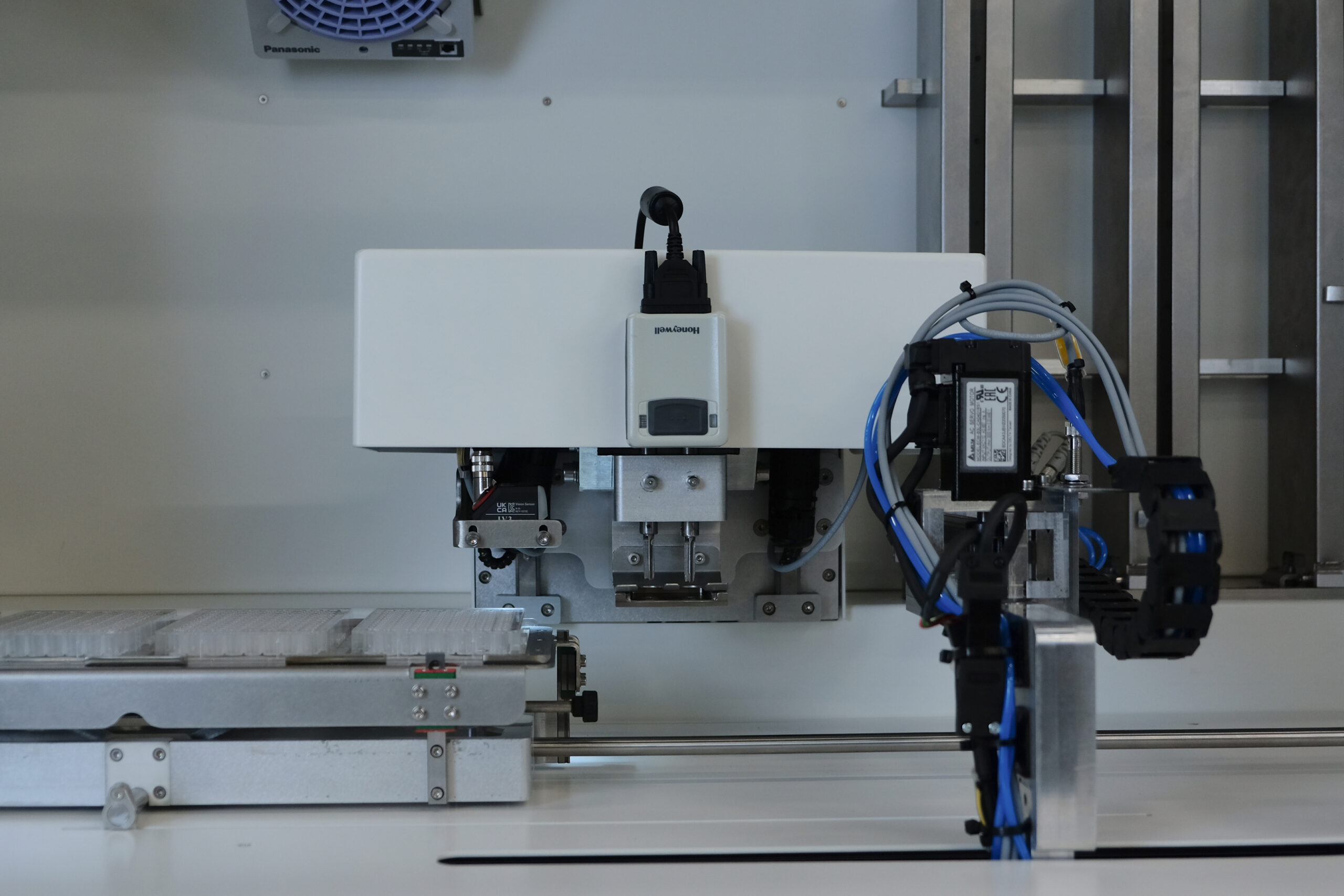

- Two cutting heads

- Ionizer

- Floor standing system

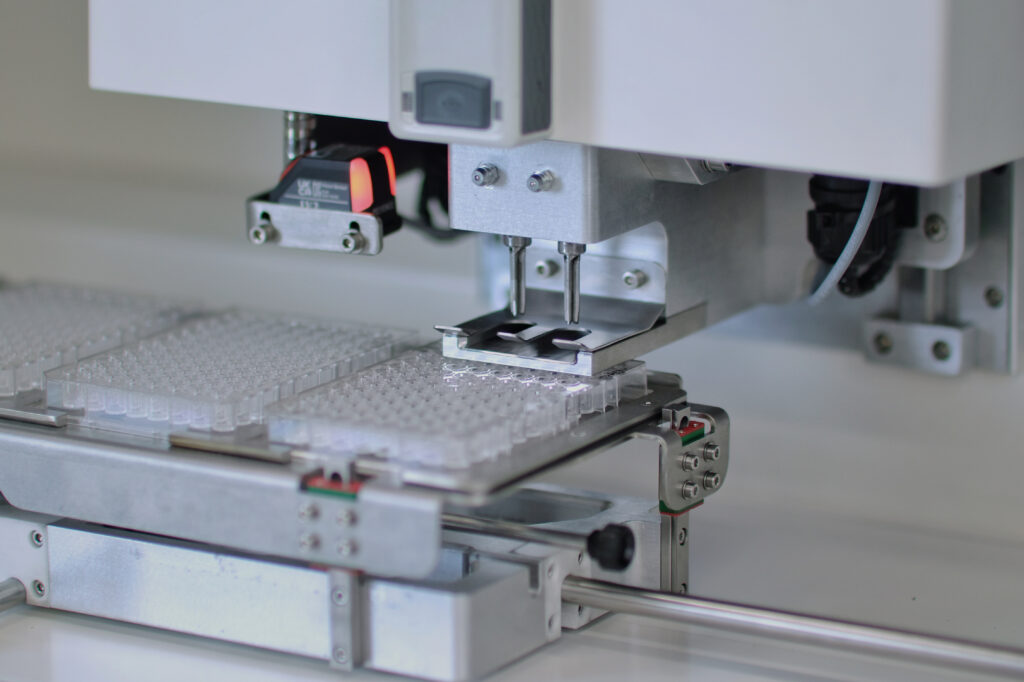

Two removable feeder

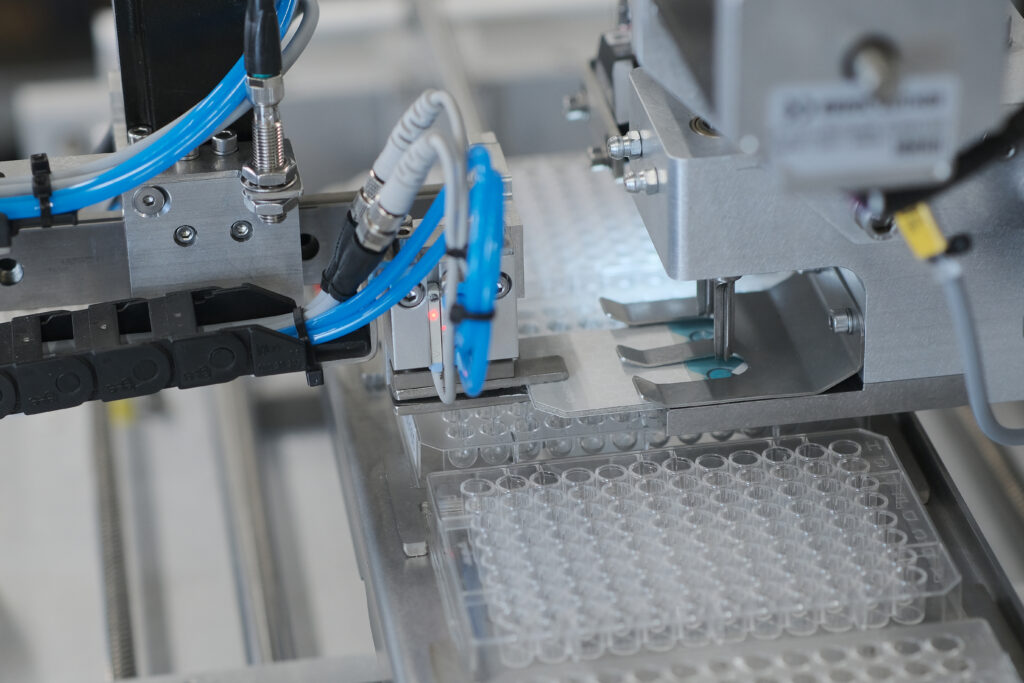

Dedicated card gripper

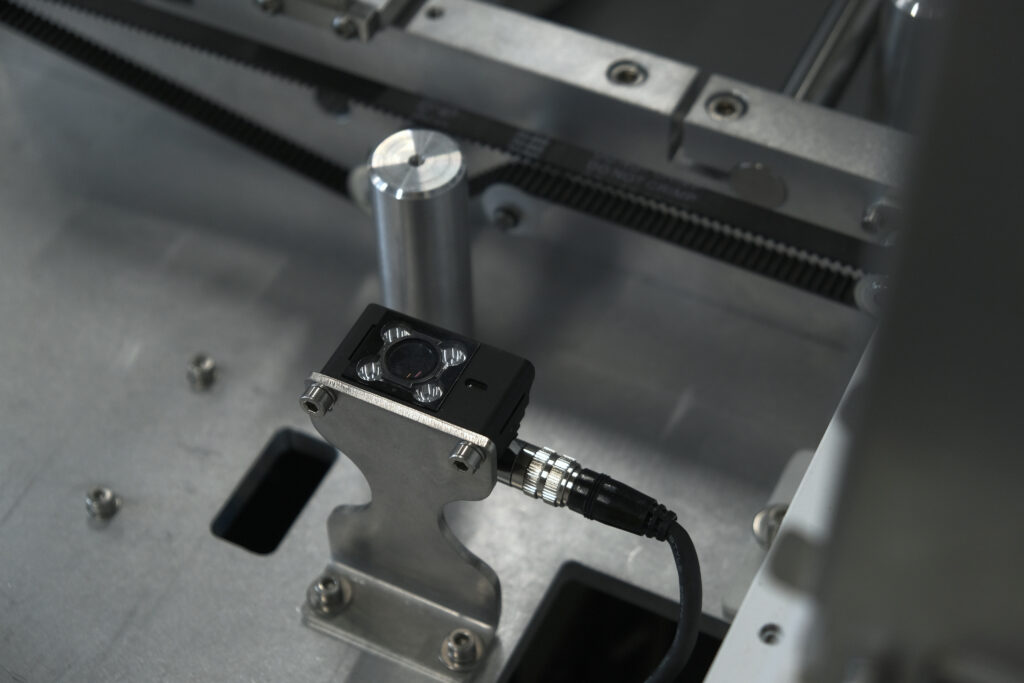

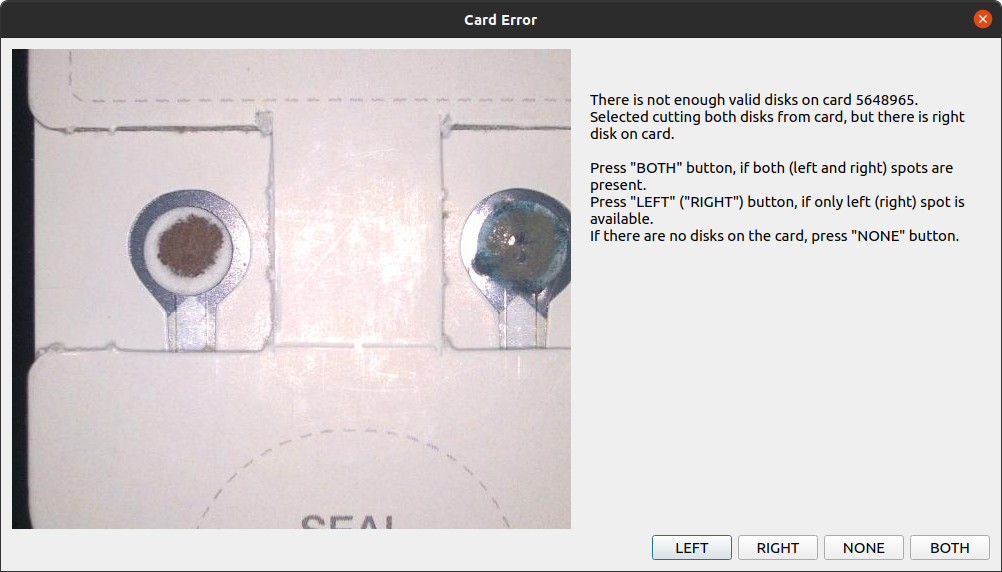

Machine vision based sample card verification

Sample qr-code recognition

Two punchers heads

- ability to cut one or two disks to a single spot

- ability to cut two disk each to a different plate

Punch verification

Safety lock

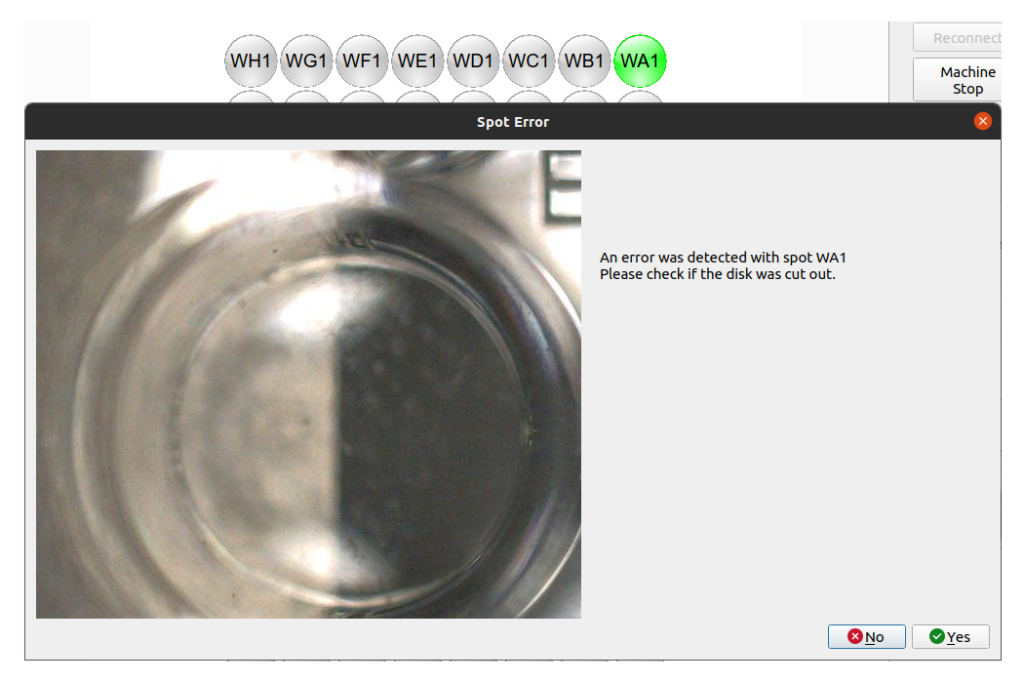

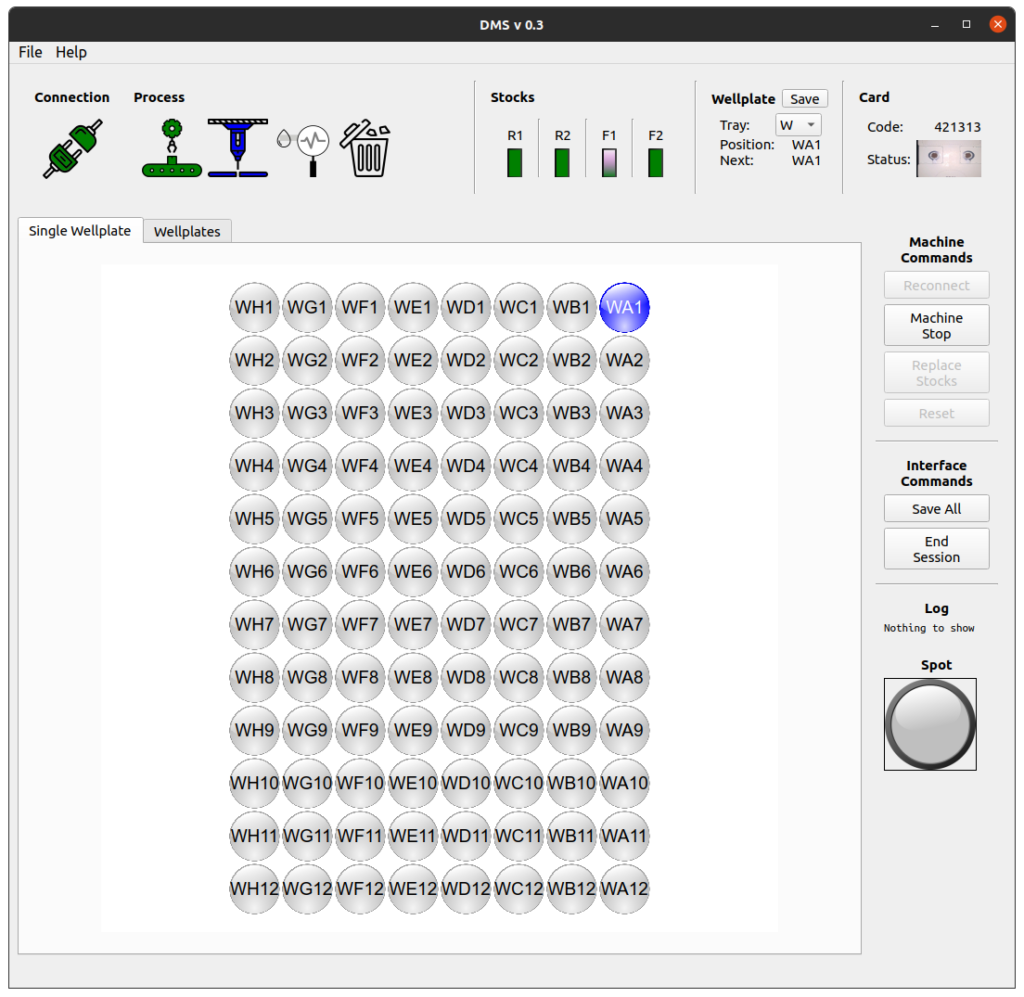

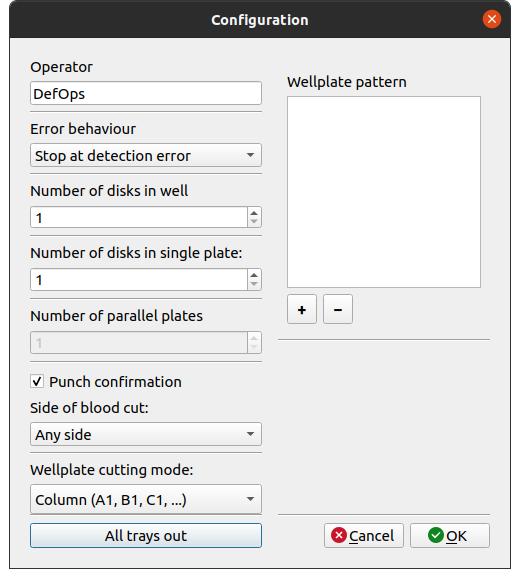

DMS Application

Characteristics

- Supervision of the processes

- Support for four 96-well plates

- Advanced cutting cycles

- Saving/reading to xlsx/csv

- Support for a plate code scanner (confirming the plate placement) and a card code scanner

- Automatic connection to the machine

Advanced options

- Defining operator

- Error behaviours

- Cutting cycles

- one or two disks to a single spot

- two disk, each to a different plate

- locking positions by rows/columns

- locking selected positions

- preserving the absence of blood on the sample

- Designing own well plate pattern

- Changing trays

Detecting card errors

Detecting empty wells